History of HMO Development

Mass production of HMOs was difficult due to their complex chemical structure. Therefore, it has not been possible to formulate them in infant formula for a long time. However, by applying our amino acid fermentation technology, we established a HMO production process and achieved mass production.†

Manufacturing process

Saccharides (starting material) → Microbial fermentation → Sterilization → Purification → HMOs

| 1998 | World 1st invention for large-scale production of oligosaccharides by fermentation† |

| 1999 | Received Nikkei BP Technology Award in Medical Biotechnology section for “World’s First Industrial-Level Production System Technology for Sugar Chains” |

| 2013 | Establishment of plant-scale production process of HMOs |

| Present | Production facility for HMOs (HOT-1) has been constructed and 2’-FL, 3’-SL and 6’-SL will be launched successively from 2023, subject to regulatory approval |

† T. Endo et al. Large-scale production of CMP-NeuAc and sialylated oligosaccharides through bacterial coupling. Applied Microbiology and Biotechnology, 53, 257-261 (2000)

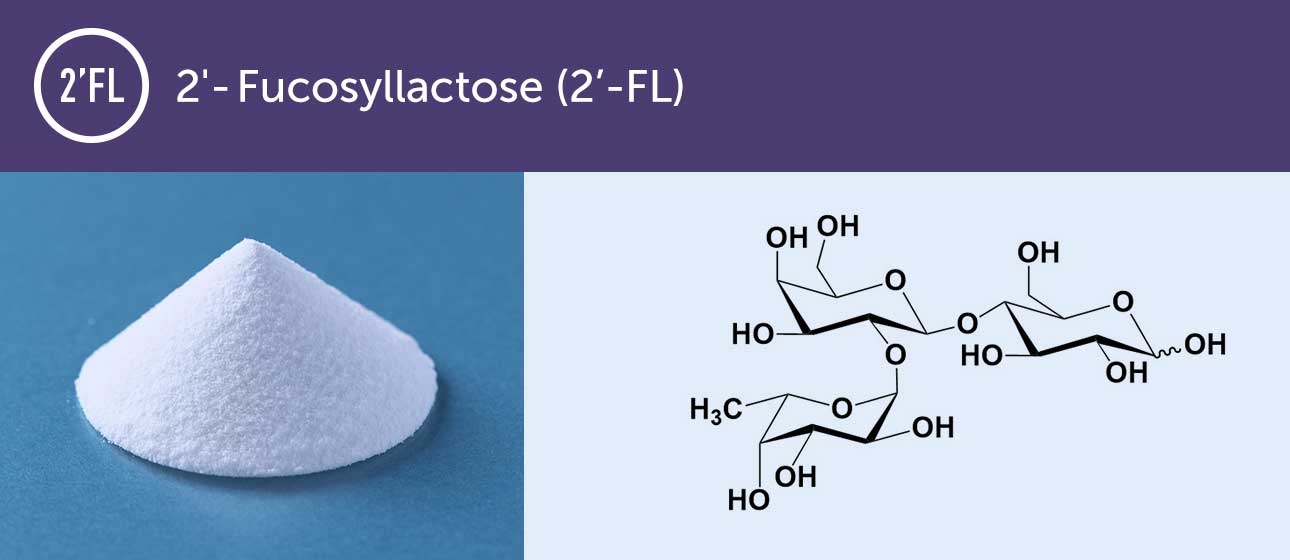

Neutral HMOs

- 2’FL is the most abundant neutral HMO.

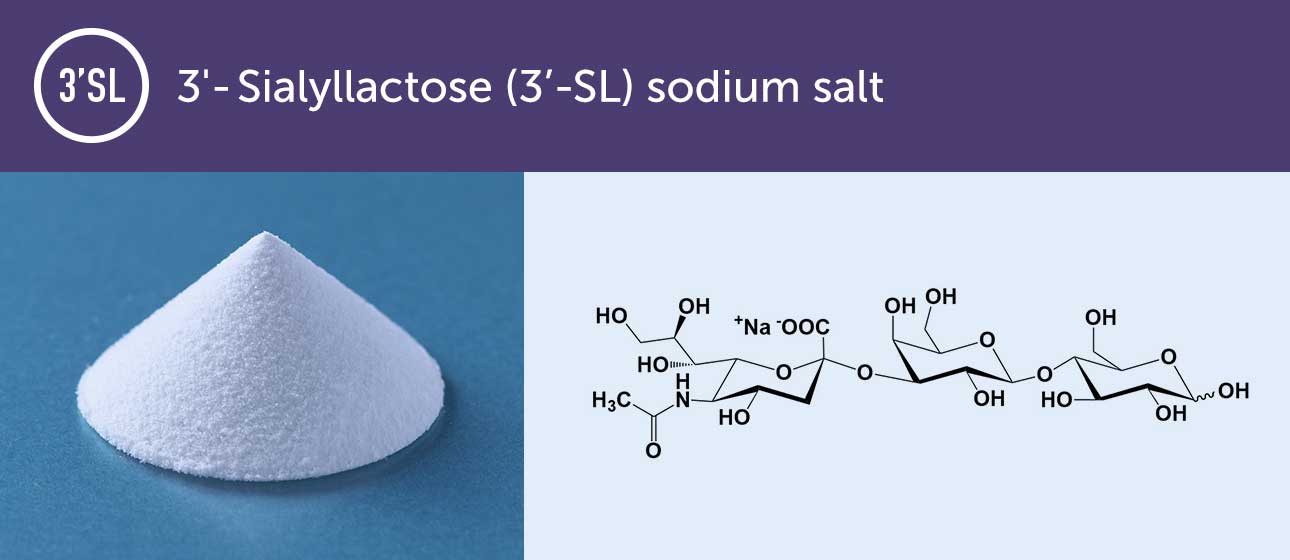

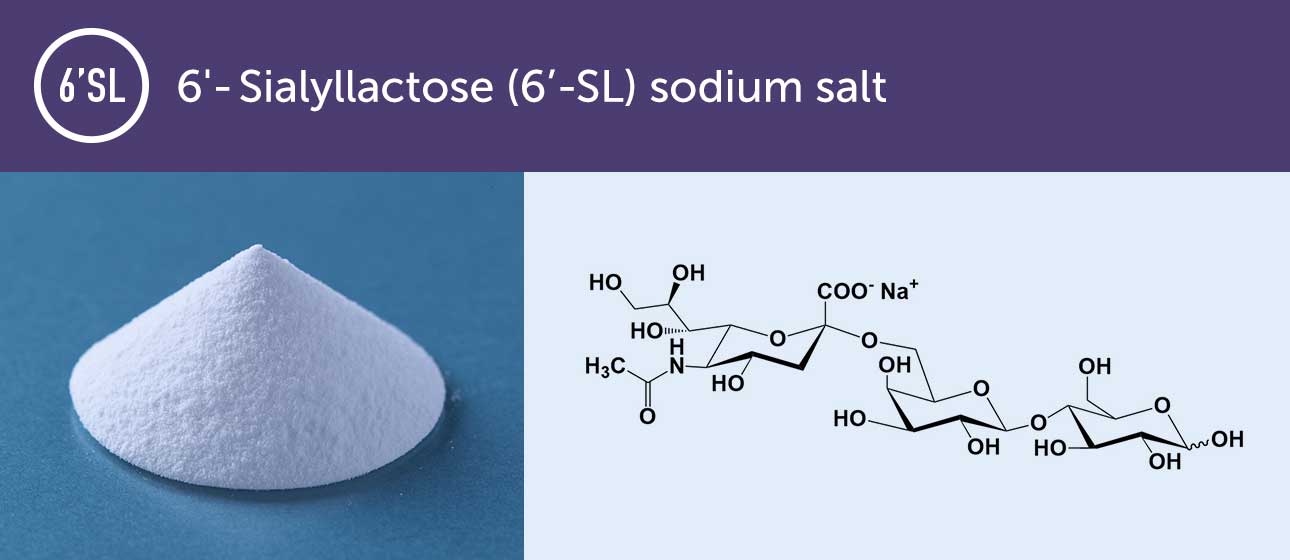

Acidic HMOs

‡ Sialic Acid: represent a family of 9-carbon sugars present in human cells. They are known as the building blocks of brain gangliosides.

- 3’SL is one of the top 5 acidic HMOs.

- 6’SL is the most abundant acidic HMO.